Features - Technical

DECEMBER 30, 2001

Lotus T88

BY PETER WRIGHT

The history of Grand Prix racing is littered with cars that were built in hope, but that never made it to the start line of a Grand Prix. Few can have tried as hard as the Lotus T88 of 1981, three of which were built and presented for racing at the Long Beach, Brazilian, Argentinian and British GP's, and rejected each time.

Team Lotus had enjoyed considerable success with the T72, winning 20 GP and three World Championships in the remarkable five years of its active life. The next two Lotus GP cars, the T76 and T77 were not so successful, though the T77 finally scored a win in Japan 1976. Chapman concluded that the cars were not using their front tires properly, the drivers complaining all the time of excessive understeer. Part of the brief for the aerodynamics was to make the new car (to become the T78) aerodynamically sensitive to pitch angle i.e. as the nose-dived under braking, the center of downforce would move forward and load up the front tires giving the driver good front-end bite. Ralf Bellamy, the car's designated designer, and I went off to the _-scale wind tunnel at the Imperial College, to find out how to do that.

The history of how this program ended up with discovering the secret of making ground effect useful on a racing car, is a whole other story. However, we managed to make the T78 much more pitch sensitive than preceding Lotus's, and Chapman asked for yet more pitch sensitivity when we started on the R&D for the T79. Again we succeeded, and the race history of both these two cars is well documented. "If some is good, more is even better," thought Chapman, and so I had the same brief for the T80. But of course, such sayings are not always true!

The T80 tried to dispense with conventional front and rear wings, and derive all it's downforce from ground effect using the full length of the car. While the downforce and L/D figures were excellent, the pitch sensitivity rocketed. The excessive pitch sensitivity, combined with sticking curved skirts running from just behind the front wheels, around the rear wheels to the extreme rear of the car, caused that driver-frightening phenomenon, "porpoising". The car would hit a bump and bounce up and down, pitching at the same time, until the driver applied the brakes. I vividly recollect Andretti reporting the front wheels leaving the road at high speed at Silverstone. Ultra-stiff springs just made it worse - the car bounced, under-damped on its tires.

While Team Lotus stepped back one pace, and raced the T81 in 1980, I set out to investigate and attempt to solve the porpoising problem. The T80 had proved that there was more downforce to be had, but unless it could be controlled it was unusable. Since 1977 I had been working with David Williams, Head of the Flight Instrumentation Department at the Cranfield College of Aeronautics. He had designed and built a digital data system for use on the T78 when it had become apparent that it would be absolutely essential to gather data from the chassis in order to progress with the development of ground effect. When the T80 porpoising started, I discussed the phenomenon with him, and he offered to model it and validate the results with the data we had. He established that it was an aero-elasticity problem, akin to flutter in an aircraft wing. The changing aerodynamic loads, as the car bounced and pitched, excited the pitch and heave modes of the sprung mass on its springs and tires.

One day he said to me "What you need is an Active Suspension", and took me into the laboratory to demonstrate an artificial-feel control column he was developing for a fly-by-wire research aircraft. He demonstrated how the control computer could provide any spring rate, mass and damping for the system, and that the technology could provide a suspension system with unique properties. But we already had a Plan A - twin chassis - and decided that Active Suspension would be Plan B (and that is yet another story).

By the time we had struggled with the T80 for a year we realized that while the body and associated aerodynamic forces required a very stiff suspension, if the rest of the car's mass was attached to that suspension it would porpoise and the driver would have an unacceptably rough ride. It was actually while I was contemplating how one might apply ground effect to a high performance road car, such as the Lotus Turbo-Esprit, that a possible solution occurred to me. Unconstrained by any performance regulations, there was no reason why a ground effect underbody could not be connected directly to the outboard ends of the lower suspension members, and not to the sprung part of the car. In this way, the problems of excessive deflection of soft road springs, and the need for skirts to maintain the gap between the edges of the underbody surface and the road would be avoided. Now, if we could do that on the racing carÉÉwhere is that rulebook?

Having read the regulations thoroughly, including a detailed look at the definitions section, I highlighted the relevant sections and went to see Chapman (his office in Ketteringham Hall was just next door to mine). One of the wonderful things about working for Colin Chapman was that as soon as you took an idea to him, he picked it up (if it was any good) and extrapolated to where it might take one, while at the same time scrutinizing it carefully for weaknesses. It was sometimes hard to keep up with his fertile mind. Within hours Martin Ogilvie (Chief Designer) and I had moved upstairs to a locked office in Ketteringham Hall, and a veil of secrecy was drawn over what we were doing.

What we did initially was to take a T81, as raced in 1980, as see how we could turn it into a mule car to develop and prove the concept. The car was to be designated the T86. Martin started scheming on his drawing board, while I initiated a wind tunnel program, while keeping him informed of critical features for the aerodynamics.

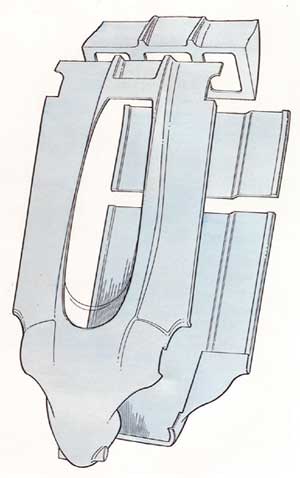

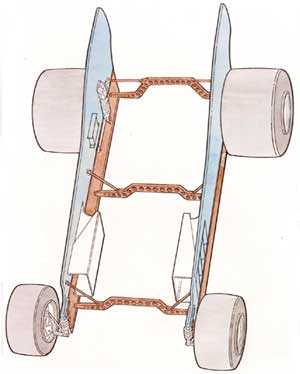

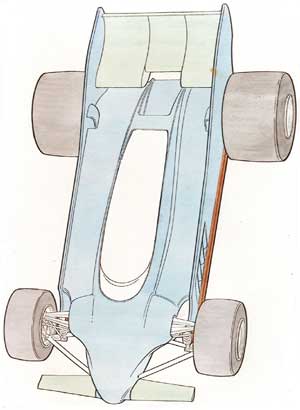

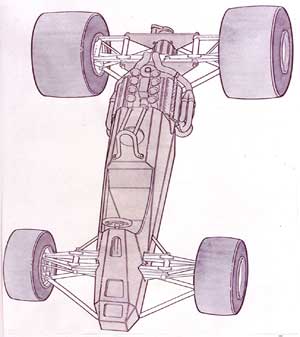

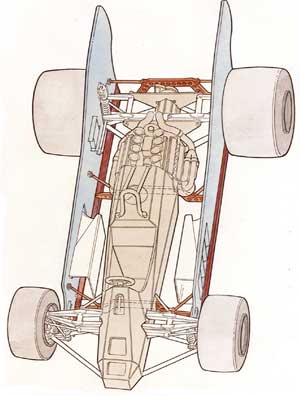

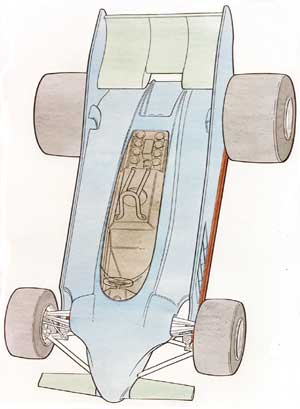

There were a number of difficult design problems to be overcome. The aerodynamics were to be based on those of the T80, with a full length body and undertray, with curved sliding skirts, and no wing as such, just a trailing edge flap on the body - very similar aerodynamically to the T80 as it first appeared. However, the body would have to be bigger to allow the sprung masses (chassis, engine, radiators etc) to move relative to and inside the body. It was not possible to build an empty shell for the body, it needed some structure to span across it, and this had to be accommodated in holes through the chassis. Radiator ducting would be a problem, with the intake and the radiator moving relative to each other. The suspension of the chassis part would be conventional, but the body could not be mounted directly to the hubs, as proposed for a road car, it had to have a suspension. The regulations stated that any part having an aerodynamic influence must be mounted to the entirely sprung part of the car. Therefore, we surmised, the body must have a suspension system. To help people think of this in the right way, we decided to describe the car as "the twin-chassis" T86 - not the "twin-body". The suspension characteristics we were looking for were very stiff i.e. just hard bump rubbers. There was nothing in the rules to say one could not have a very stiff suspensionÉ..yet.

The T86 consisted of a T81 monocoque, with the engine spaced off the back of the fuel tank to allow a crossbeam to pass between the two. Additional crossbeams passed through the monocoque, under the driver's knees, and over the gearbox. The body was manufactured in CFRP/Nomex honeycomb sandwich, a first for Team Lotus. Chapman persuaded Cosworth to rearrange the pumps on the DFV, to tuck them in closer to the block, so that the undertray could fit closer around the engine.

An exclusive test session was booked at Jarama, away from prying eyes. After initial problems with the revised oil pumps were overcome, and the car stopped filling its undertray with oil (it was nick-named the Torrey Canyon, after an oil tanker that shed its cargo off the British coast having hit some rocks), the performance straightaway showed great promise. The curved skirts were, as usual, a problem to get working reliably, but the downforce was there and the car did not porpoise. The decision was made to proceed to a new racecar, based on these principles, and including sliding skirts. Out of the blue, FISA (as the sporting branch of the FIA was then called) banned skirts. To accomplish this, they made a rule that stated that all cars must have at least 6 cm clearance to the road, but did not state when it would be measured - in the Pits was obviously the only practical opportunity. It took us about 30 seconds to realize that in the twin-chassis concept we had the perfect solution, provided we could come up with a suspension system for the body that raised it at low (Pit Lane) speeds, and that allowed it to sink down onto the bump rubbers at racing speeds.

The characteristics we were after were a very low rate, but sufficient pre-load to raise the body up the 6 cm. We wanted it to go down fast, and come up slowly, to ensure it stayed down if speeds dropped momentarily. It needed very soft bump damping, and very stiff rebound. We found these characteristics in the type of pressurized gas strut used for hoods and tailgates on road cars, and found a supplier who was prepared to tailor the exact characteristics we required. As the drawing office and factory at Ketteringham Hall geared up to produce the T88s for the 1981 season, a security clamp down was put over the whole project. Rumors abounded, as a result of the Jarama test, but exactly what Team Lotus was up to never emerged. So paranoid had everyone become about the new no-skirt regulations, and how to stop people getting around this most ambiguous and unenforceable regulation, that Ferrari managed to persuade FISA to add a regulation at the last minute that stated that cars must have a suspension system. Ferrari was convinced we were going to build a Formula 1 Kart. That regulation survives today, but I don't know of any designer ever wanting to build such a car.

It was around this time that we had realized the deficiencies of a monocoque built in aluminum sheet, when subjected to ground effect loads and suspension stiffness. One day, Martin Ogilvie took a piece of the T86's undertray material and bent it until it folded along the failure line. The outer CFRP skin folded and the inner skin buckled inwards. Showing it to me (we were still in the upstairs, secret office) he said: "We could make a monocoque like this by cutting the inner skin, folding the sandwich material, and jointing the inner skin again with a lap joint." I agreed, and Chapman leaped at the idea. That was November, and the first race was just 5 months away.

Martin set about designing a monocoque using this construction technique - the skin of the monocoque would be folded up out of a single sheet of composite honeycomb - and figuring out how to bolt in the machined aluminum bulkheads. I was tasked, thanks to my composite experience, with researching how to make the composite sheet, and developing a material specification for it. I had the best of Lotus' composite people available to help.

Unlike McLaren's approach to their first CFRP monocoque, which employed the aerospace expertise of the Hercules Corporation and pre-preg. CFRP, Lotus decided to develop their CFRP tub in house - there was no time to do otherwise. We decided that we needed to mold the flat sheet on a large piece of plate glass, to give the precision and surface finish we required. The skins were hand laid, using epoxy resin, and the Nomex honeycomb vacuum-bagged to bond it to the skins. The first attempt showed that we were not using the correct release agent, and I had to go and ask Chapman to authorize another sheet of expensive plate glass as the original one shattered while trying to remove the molded panel. He was not impressed. We finally found a suitable release agent, just one day before the first monocoque was due to be made.

With little knowledge about the impact performance of CFRP, and the disastrous and all too recent experiences of Rolls Royce with their RB211's CFRP fan blades being in everyone's mind, we decided we needed to develop a skin specification that was at least as good in a crash as aluminum. There were no FIA frontal impact tests to pass at that time. I asked Chapman if I could build a 15m tower, with a pole down the middle, so that I could drop a 100kg concrete block onto samples representing different monocoque constructions. He rolled his eyes and then smiled - this was the sort of R&D he loved. We made box sections of aluminum, aluminum/honeycomb, carbon fibre/honeycomb, Kevlar/honeycomb and hybrid carbon and Kevlar/honeycomb. This is when we first discovered that carbon fibre is just as good at absorbing impact energy as aluminum, provided it is constrained to fail in the right way - the honeycomb stabilization ensured that it crushed progressively. In the end we went for the hybrid carbon and Kevlar/honeycomb as the Kevlar strands in Courtauld's specially woven fabric tended to hold the pieces together after an impact. It has since been shown that it was not really necessary but there was no time to do further research.

When the monocoque torsion test was carried out, it was found to be below the desired stiffness. ±45 degree unidirectional filaments were laid up around the outside surface in the cockpit area, and this solved the problem. Subsequently, they were incorporated into the initial lay-up, but the ability to make this correction to the structure at the last moment impressed all with the potential of composite monocoques, if not with the ability to carry out the stressing of it!

First test for the T88 was at Ricard, in the South of France. I remember that Alfa Romeo was also there to test their 179/C. A few photographers were present, and we closed the garage doors to prevent them prying. To keep them entertained, the mechanics lifted the door, shortly before the car was due to run, and four of them emerged wearing the body top, their heads sticking out of the long cockpit opening. It rained a lot, and when the car first ran, it was on a damp track. Alfa immediately sent out their car to "calibrate" the T88's performance and, if I remember correctly, the T88 was about 1 second a lap quicker! That's when the campaign to prevent the T88 racing really started.

The story of how the Lotus T88 was prevented from racing is not a savory one, exposing some of Formula 1's less acceptable traits. Also, many of the individuals involved are still living, and my legal fund is not that large, so I will not recount all the details of that difficult period! A catalogue of Chapman's determined attempts to race the T88, and the steps taken to stop it will perhaps best serve to show just how important the right to innovate within the regulations was to Chapman.

Every independent technical judge, and indeed every independent legal person, judged that the T88 was allowed under the regulations. In the first FISA Appeal the findings were found to be incorrect, due to using the wrong interpretation of the French language version of the regulations (the English version is the definitive version). Chapman, being a logical engineer, believed that logic and right would prevail and he was fighting for the right to try new ideas, even if 9 out of 10 did not work. Quite simply, that is why he went racing. He was prepared to jeopardize Team Lotus' whole season, and possibly its future, to fight for that right. He was particularly incensed that, while the T88 was judged illegal, Brabham were permitted to race a car that raised itself hydro-pneumatically to pass the 6cm test in the Pit Lane, and then lowered itself on the track, and ran flexible skirts. After he lost, in the face of a coordinated effort by his competitors and the Formula 1 organization, he never again really enjoyed Formula 1 racing. He went off to develop his new interest - ultralight aircraft - in which he immersed himself right up to the day he died in December 1983.

To put the T88 saga into some perspective, it should be remembered that in 1980 and 1981, FISA and FOCA were at war. The no-skirt regulation was part of that war, FISA introducing the rule without consultation with FOCA. They were possibly influenced by Ferrari, which was on the side of FISA and being beaten by the ground effect FOCA teams. The twin-chassis concept drove a coach and horse through that regulation, although it had not been originally conceived to do so. I believe both sides in the FISA-FOCA war agreed that it should not be allowed, in the interests of trying to gain some stability in Formula 1. It was an interesting experiment, one that I never found out whether it worked. Now, 20 years later, Steve Hitchins is showing that it just might have revolutionized Formula 1 design.